Production Process Guidance yeLeaf Springs

-Kureba (kureba uye kupfupika tapering)(Chikamu 3)

1. Tsanangudzo:

Tapering/Rolling process: Kushandisa muchina wekutenderedza kutaper chitubu chakafuratira mabara ehupamhi hwakaenzana mumabhawa ehukobvu hwakasiyana.

Kazhinji, kune maitiro maviri ekutapa: nzira refu yekureba uye pfupi tapering maitiro. Kana iyo tapering kureba kupfuura 300mm, inonzi refu tapering.

2. Application:

Mashizha ose echirimo.

3.1. Inspection before tapering

Usati wakunguruka, tarisa chiratidzo chekuongorora che punching (drilling) yepakati gomba rechirimo flat bars mune yapfuura maitiro, ayo anofanirwa kuve akakodzera; panguva imwecheteyo, tarisa kana iyo yakatarwa yemaspring flat mabawa inosangana nezvinodiwa rolling process, uye iyo rolling process inogona kutangwa chete kana ichinge ichisangana nezvinodiwa maitiro.

3.2. Kutuma arolling machine

Zvinoenderana nezvinodiwa zvekutenderedza, sarudza nzira yakatwasuka kana parabolic rolling. The trial rolling ichaitwa nekuguma positioning. Mushure mekunge kutongwa kwemuyedzo kwapfuura kuzviongorora, kuchaendeswa kune inspector kuti aongororwe uye atenderwe, uyezve kutenderera kwakarongeka kunogona kutangwa. Kazhinji, kubva pakutanga kwekutapa kusvika pakukunguruka kwezvidimbu makumi maviri, zvinodiwa kuti ushingaire pakuongorora. Paunenge uchitenderedza 3-5 zvidimbu, zvinodikanwa kuti utarise saizi yekutenderedza kamwe uye kugadzirisa muchina wekukungurutsa kamwe. Rondedzero yekuongorora inogona kuitwa zvichienderana neimwe frequency chete mushure mekutenderera kureba, hupamhi uye ukobvu zvakagadzikana uye zvinokodzera.

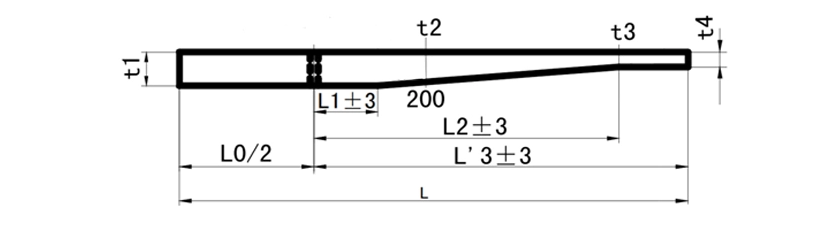

Sezvinoratidzwa muFigure 1 pazasi, iyo parameter kuseta yeLeaf spring rolling.

(Mufananidzo 1. Kutenderedza paramita dzechitubu cheshizha)

3.3.1. Tsananguro dzekukunguruka ukobvu

Rolling ukobvu t1 ≥24mm, kudziyisa nepakati frequency choto.

Rolling ukobvu t1<24mm, iyo yekupedzisira yekupisa choto inogona kusarudzwa yekudziya.

3. Tsananguro dzezvinhu zvekukungurutsira

Kana nyaya yacho60Si2Mn, tembiricha yekudziya inodzorwa pa950-1000 ℃.

Kana zvinhu zviri Sup9, tembiricha yekudziya inodzorwa pa900-950 ℃.

3.4. Rolling uyekucheka magumo

Sezvinoratidzwa mumufananidzo 2 pazasi. Isa kumucheto kwekuruboshwe kwebhari uye utenderedze rutivi rwakapisa rwerudyi rwebhari maererano nezvinodiwa. Mushure mekunge tapering inosangana nezvinodiwa saizi, cheka magumo ekurudyi maererano nehukuru hwekugadzira. Saizvozvowo, kupeta uye kupera kwekucheka kuruboshwe bhari rakafuratira richaitwa. Zvigadzirwa zvenguva refu zvinoda kutwasanudzwa mushure mekukunguruka.

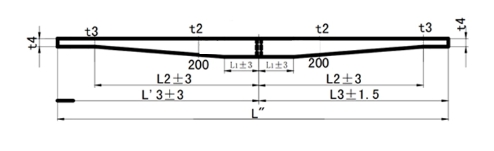

(Mufananidzo 2. Tapering parameters yeshizha chitubu)

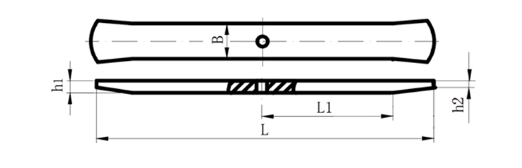

Kana iri pfupi tapering, kana magumo ekucheka achidikanwa, uye migumo ichagadziriswa maererano nepamusoro nzira. Kana kupera kwekupedzisira kusingadiwi, magumo emashizha emashizha anoita sefani. Sezvinoratidzwa mumufananidzo 3 pazasi.

(Mufananidzo 3. Zvikamu zvipfupi zvechitubu cheshizha)

3.5. Material Management

Zvigadzirwa zvekupedzisira zvakakwenenzverwa zvinosungirirwa pane rack yemidziyo ine yakadzika-yakatwasuka nzvimbo yakadzika pasi, uye yekuongorora yekumisikidza mamakisi matatu (kureba, hupamhi uye ukobvu) ichaitwa, uye kadhi rekutamisa basa richanamirwa.

Zvinorambidzwa kukanda zvigadzirwa kumativi, zvichikonzera kukuvara kwepamusoro.

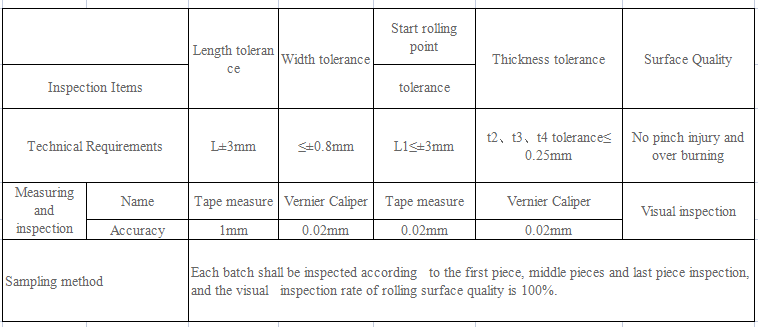

4. Mitemo yekuongorora (Tarisa kune chiyero: GBT 19844-2018 / ISO 18137: 2015 MOD Leaf Spring - Technical Specifications)

Edza zvigadzirwa zvakapedzwa maererano nemufananidzo 1 uye Mufananidzo 2. Maitiro ekuongorora ezvigadzirwa zvakaputirwa zvinoratidzwa muTebhu 1 pazasi.

Nguva yekutumira: Mar-27-2024